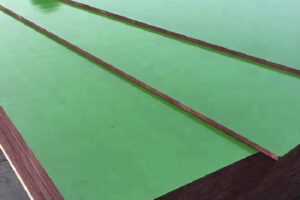

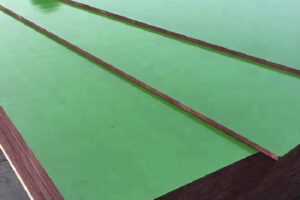

PP Plastic Film Faced Plywood is a new type of film faced laminate. Compared with traditional film faced laminates, it has the following advantages:1. Easy to demould, release agent free, nonstick cement, concrete surface is very smooth.

2. More reuse times than normal film faced plywood.

3. Waterproof performance is perfect and wear resistant

2. More reuse times than normal film faced plywood.

3. Waterproof performance is perfect and wear resistant

| Name | PP Plastic Film faced plywood |

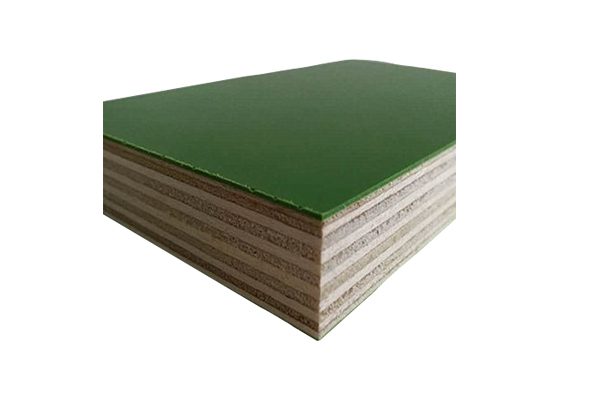

| Core | Poplar, Combine (poplar and hardwood mixed), Hardwood |

| Surface Material | PP ( polypropylene) |

| Size | 1200x2400mm, 1220x2440mm(4’x8′), 610x2440mm(2’x8′), 1250x2500mm, 915x1830mm(3’x6′) or as per your requirement |

| Thickness | 9mm/12mm/15mm/17mm/18mm/21mm/24mm/27mm/30mm or upon request |

| Density | 530~650kgs/cbm |

| Edge | Sealed with water proof paint and paint color can be upon request |

| Glue | WBP-PHENOLIC, WBP-MELAMINE, MR |

| Hot Press | one time / two times / three times press grade |

| Formaldehyde Emission | E0,E1,E2 |

| Moisture content | 8%-12% |

| Application | Construction, formwork, Moulds, Furniture |

| Delivery time | Within 2-3 weeks upon deposit or upon opening of L/C |

| Min Order | 1*20’ft |

| Payment Terms | TT or L/C |

| Supply Capacity | 5000cbm/per month |